Septic Tank Pumping Pros: Grease Trap Service

Published by Daniel Sexton III,

Septic Tank Pumping Pros: Grease Trap Service

http://septictankpumpingpros.blogspot.com/2018/11/grease-trap-service.html

Grease Trap Service

Grease Trap Service Procedures Explained

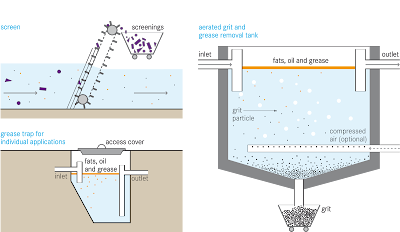

It is important to grasp that the grease interceptor's effectiveness recedes as the trap is chock full of (FOG), and when it is topped off to its capacity, it will no longer divide any (FOG) from the liquids. The technician may not grasp that the grease trap is full, that being said, as it will store water even after it becomes totally full, sending the unfiltered FOG straight into the sewer system. Together with because grease fills up the interceptor from the top level of the trap tank to the bottom level down (combined with variations in FOG weight ), it can be hard to realize the moment the trap needs to get cleaned.

Moreover, unfortunately, washing grease interceptors, primarily sizeable traps, is an uncomfortable ordeal that may possibly necessitate eatery business to momentarily cease, so this kind of essential cleaning work is quite often passed over. In certain cases, also, in the middle of the pressure of a restaurant environment, the chore in regard to sprucing up the grease trap is simply ignored.

The water system niche standard says that interceptor holding tanks should be cleaned whenever twenty-five percent of the tank's total volume is inhabited with (FOG) (and 75 percent% by water). Grease traps may need to get serviced prior to reaching this threshold, nevertheless, and so the service professional may really need to monitor the trap, particularly grease buildup on the existing baffle, to decide on an ideal cleaning schedule for the business. Hydro jetting a grease interceptor as a component of ideal care is a required task.

After dismantling the grease interceptor, the membrane of (FOG) really should be loaded into a watertight sack or bottle and thrown in the garbage. Unlike "yellow grease" collected coming from deep-fat fryers that can be utilized in the synthesis of diesel, cleansing soap, and rubberized products, FOG is not able to be recycled and it must be tossed in the garbage. The interior sides, infiltrators, and cap ought to then be cleaned of (FOG) and sterilized.

Rubberized gloves should be used and cleaning soap and antibacterial elements should be minimized during the cleansing task. When the grease trap interceptor is re-assembled, precaution ought to be taken to arrange the parts properly as, once flow is carried on, misaligned components may warrant overflowing and dirtying of FOG within the cooking area.

While cleaning FOG interceptors, care should certainly be required to steer clear of stress locations generated by burdensome manhole caps and to refrain from ruining the silicone lining which keeps odors from escaping above solid ground. Any significant items identified at the end of the interceptor storage tank should be purged. One business disclosed having uncovered a trike in their storage tank.

To lessen the necessity for cleaning the grease interceptor, half-done meals, animal fats, baking fat and lard lingering in kettles and roasters need to be wiped with paper towels or rinsed out with hot water and placed right into the garbage just before using the commercial dishwashing sprayer. This precaution can substantially lessen FOG being let into the tank and help prevent the production of stinky sulfur compound fumes into the commercial establishment.

In review, FOG catches and grease interceptors are plumbing related gadgets called for in food service facilities that protect against fats, oils, and grease from going into the municipal sewage infrastructure. InterNACHI examiners and establishment owners really should understand the way these grease interceptors work and how they are repaired, retained and examined.

Dan Sexton III would like to thank all our existing and new grease trap cleaning service customers all up and down the East Coast of the United States.

via Septic Tank Pumping Pros https://ift.tt/2mjUFbl